F150 Sectioning and Finishing

By: Rob Corrigan

By: Rob Corrigan

Project at a Glance :

This is a project for a 11th and 12th grade Auto Body Class working on steel sectioning. It explores how a vehicle is designed and the process of measuring, cutting, grinding, welding, and corrosion protection. It allows students to investigate the best process to fix a damaged vehicle with rust, while partnering with the owner and industry to address the problem collaboratively. The project will depend on Math: measuring, time, and ratios. There will also be a VPA speaking standard for communicating to the outside stake holders. This unit is roughly 9 weeks.

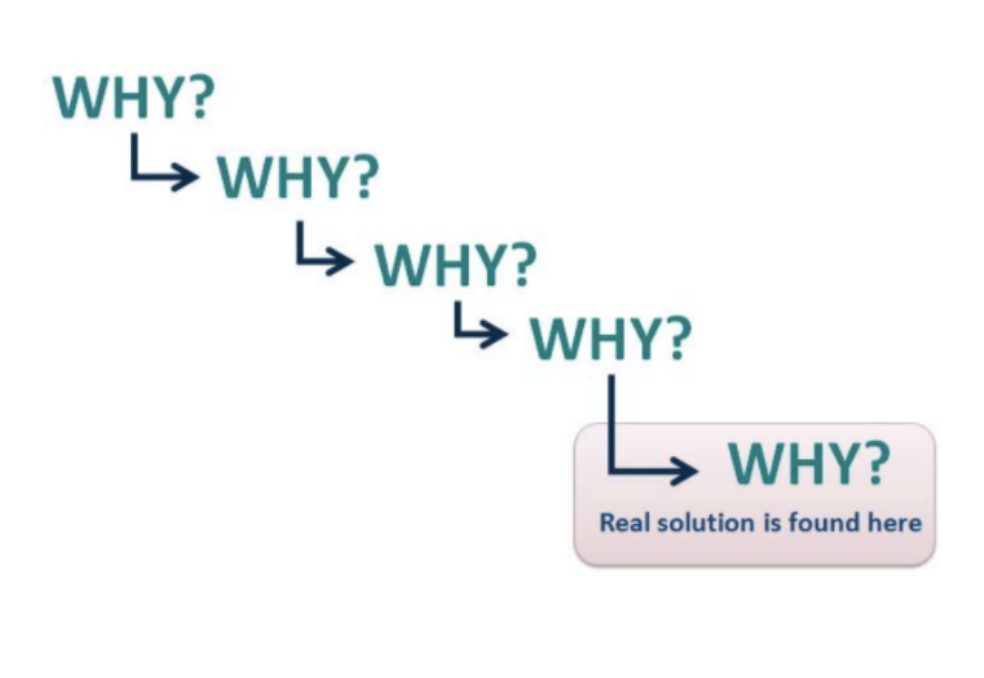

Driving Question:

How do we make a car safe and looking good?

|

Standards:

Entry Event:

|

Stakeholders:

|

Incubation:

|

|

Solution Building:

|

Authentic Audience:

|

Click here for teacher's full plan.

Reflection and Feedback:

|